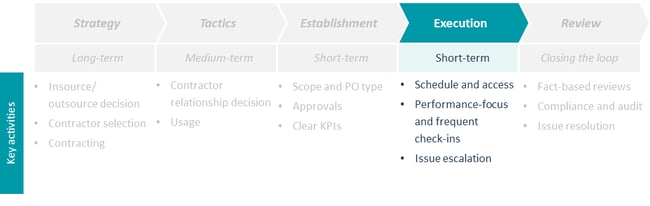

Effective use of contractors requires strategic decisions, establishing the right conditions for success and tight execution management once they start coming onsite.

In this blog series, we’ve strategically chosen contractors who can deliver the right balance of quality and cost, while managing our risk (e.g. setting up panels where appropriate). We’ve also established results-oriented working norms (e.g. reviews with meaningful KPIs) and tools (e.g. automated approval and access control systems).

Execution

Now that our chosen contractors are coming onsite to do the job, we have to actively exercise control and manage their performance to deliver projects efficiently and effectively.

1. Exercise controls

The simplest control is making sure only people who need to be onsite are onsite. If we let a contract worker onsite they’ll go to work and charge us for it. We need to stop them from getting onsite if there isn’t an active contract or purchase order for them to be working on. If we have multiple active POs with them, we need to record which one they are onsite to service. It’s pretty difficult to accurately track what one worker was doing for which PO a month later when the invoice arrives.

It’s harder to make sure that people aren’t staying onsite longer than they need to, but this is both a safety and a cost issue. Contractors causing significant safety issues clearly need to be removed. We are also at risk of incurring overtime costs if we don’t tightly control who stays onsite past schedule.

In the previous blog, discussing establishment, we looked at an example where one of our clients tightened their access control policies and invested in technology to support those controls. That system automatically raised a red flag if someone unauthorised tried to get onsite. It also made it easy for contract managers to check if a contractor was at risk of running overtime for the week – and that made it easy for the contract managers to work on overtime with the contractors. Over two months, overtime spend fell 60% (with no impact on delivery).

2. Consistent fact-based performance discussions

People are people. They don’t turn into high-performance robots the moment we label them “contractor”. We still have to monitor and manage contractor performance.

We set up the right KPIs to measure performance in the Strategy phase and maybe tweaked them in the Tactics phase. We translated the KPIs into short-term targets in the Establishment phase. Now comes the hard part – frequent fact-based performance reviews in the field.

We’ll never get anywhere ducking the performance issue. We don’t get what we want, and it’s also unfair on our contractors because if we never tell them they’re underperforming, they’ll never find out in time to fix it.

One of our clients, emerging from a crisis, found themselves with highly variable contractor performance across different parts of their business. The issue was simple to identify yet hard to resolve. In many areas, performance reviews ignored important KPIs, weren’t frequent enough, or were between the wrong people. Solving it requiring training, standardising performance review materials and processes, and hiring more experienced contract managers.

With the right tools and processes in place, contract managers can examine and record performance in a consistent way every day, and can have consistent fact-based discussions with the contractors every day. Not confrontational discussions, but not cosy. That is the secret – consistent fact-based performance discussions. As often as needed for as long as needed. No more, no less.

It was a challenging journey for our client and the contractors but it was worthwhile. Within six weeks for a pilot group, productivity and quality performance both improved 15%.

In the last blog, we’ll close out this series with a look at the Review phase, and how we can use periodic review meetings and processes to close the loop on performance management and inculcate continuous improvement.

Click through to read other blogs in this series:

Ben Thompson

Ben Thompson has 25+ years’ experience in strategy, operational improvement and line management roles. He has worked across many industries, including gambling, information technology, banking, insurance, manufacturing, education and the non-profit sector.

Linkedin