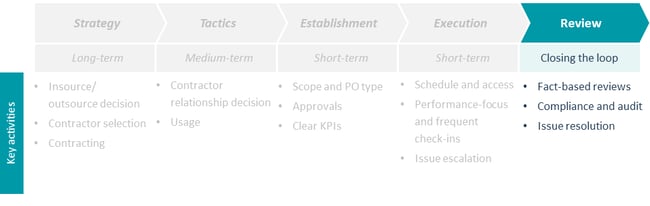

We started this series on great contractor sourcing and management with a structured yet uncomplicated approach to strategically choosing contractors who can deliver the right balance of quality and cost, while managing our risk (e.g. setting up panels where appropriate).

We then established results-oriented mechanisms and tools (e.g. automated approval and access control systems), and actively managed performance in the field (e.g. with frequent KPI-driven performance discussions).

Now it’s time to close the loop, and this series, as we explore the fifth and final component: Review – the processes and systems we use to drive continuous improvement.

Review

Great contractor review is much more than in-the-field performance review. We need reviews cascading up and back down management levels for two fundamental purposes:

- Ensuring compliance with contractual terms and good governance principles

- Driving continuous improvement and ongoing learning

1. Compliance

Some compliance issues we can handle in the field (e.g. rigorous overtime control) but others take a while to emerge.

Are contractor invoices accurate?

Contracts are full of special cases and complex clauses. It’s easy to make a mistake whether you’re submitting or approving.

One of our clients had implemented a new contractor management system and found they were receiving invoices with many and varied equipment and material claims. Occasionally the claims were ‘imaginative’ (e.g. a decorative fountain), but a typical problem related to small tools (some contracts allowed small tool claims, some didn’t).

A significant challenge was that the submitted supporting documents were effectively free-form. We recommended OCR plus targeted automation to flag inadequate (or potentially ‘imaginative’ claims) and to test potential issues like small tools claims against a contract rules database.

Are we managing change orders tightly?

It’s impossible to specify every job perfectly and perfect specification can add disproportionate cost, but work under a change order is typically more expensive and also tends to result in delays. We should always test if and how much change is really needed.

One of our clients found their major equipment repairs on average cost 50% more than planned because poor scoping was leading to material change orders on many repair jobs. Around 10-20% of that cost was avoidable through better scoping and scheduling.

We can enlist our contractors to reduce change orders through an appropriate KPI, with a target and a consequence. For example, if a contractor has a target of change orders not exceeding x% of cost, with a potential rate penalty, they may find it more attractive to help us scope and schedule jobs well.

2. Continuous improvement

Continuous improvement is central to Partners in Performance. We’re going to look at a few features of that enormous topic in the context of contractor management.

Inclusion

The most important thing is to bring our larger contractors, especially our true partners, into our continuous improvement process. We actively want our contractors to improve themselves and also to help us improve more broadly.

Part of the trick is to have an improvement KPI (e.g. total cost per unit). And a target. With mutual trust, we can and should be willing to share the upside, not just enforce downside consequences.

One of our clients had a committed continuous improvement champion who had developed such trust with their leading contractors that they regularly held continuous improvement sessions, including competing contractors. They consistently drove improvements as a group but when the champion left, that trust faded and the process lost momentum. Visibly recommitting dedicated resources to the process rebuilt trust – and results.

Learning

During the review process, we learn two important things:

- How good our contractors are

- How good we are

In our second post (on tactics), we discussed comparing our contractors (“rate and rank”) on a regular cycle (say, every six months), and who we use and how much we use them on that basis.

We also need to be honest with ourselves.How good were we at choosing our contractors, at defining our contracts with them … the whole contractor management process? It can be uncomfortable but in our learning cycle, we need to learn from ourselves and from our contractors about how to be better contractor managers.

And that takes us right back to the start of our series! Great contractor management starts with the strategic decisions on outsourcing, contractor selection and contracting. A collaborative continuous improvement mindset sets us up for great ongoing contractor management.

Great strategy enables great management, and great management enables great strategy.

Click through to read other blogs in this series:

Ben Thompson

Ben Thompson has 25+ years’ experience in strategy, operational improvement and line management roles. He has worked across many industries, including gambling, information technology, banking, insurance, manufacturing, education and the non-profit sector.

Linkedin